Top 3 Portable Power Station Manufacturer In China

- BYD LiFePO4 Battery Cells Directly Supplied | Code Verification + Video Factory Inspection

- 200 Units Low MOQ | Support Exclusive Distributor for Large Models

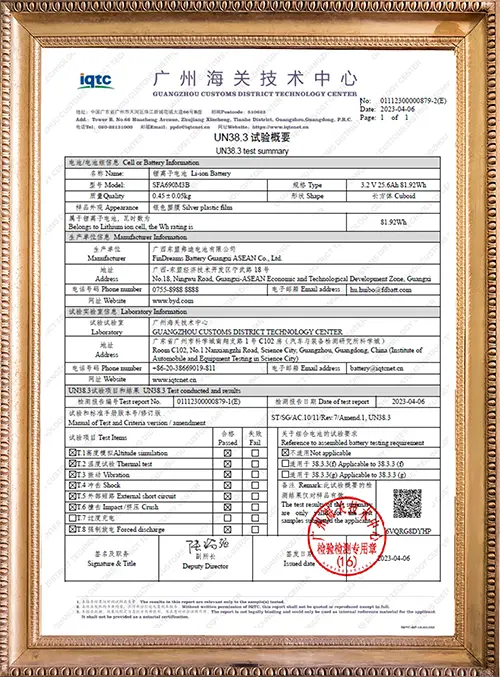

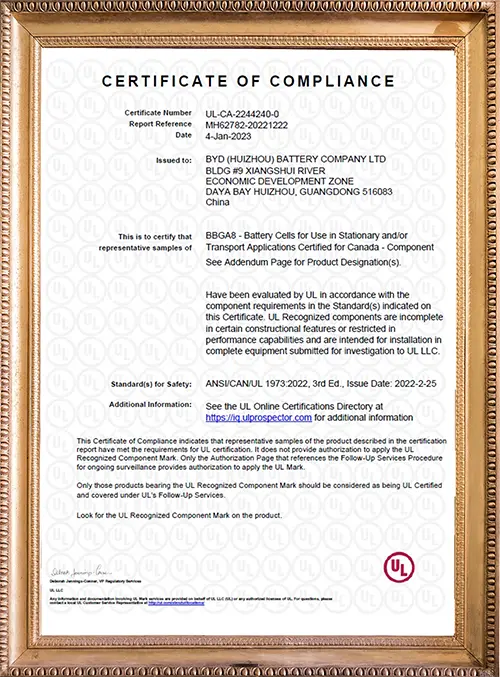

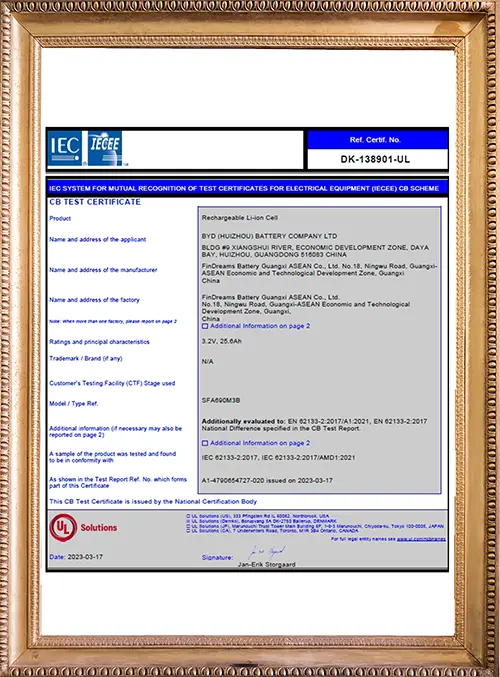

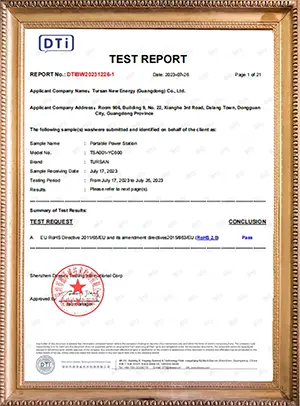

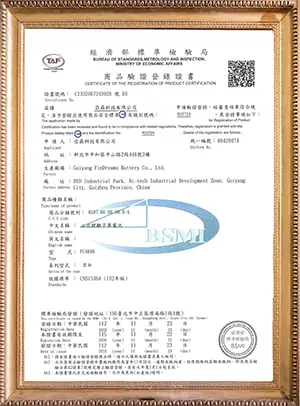

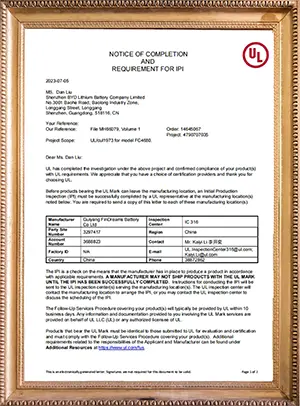

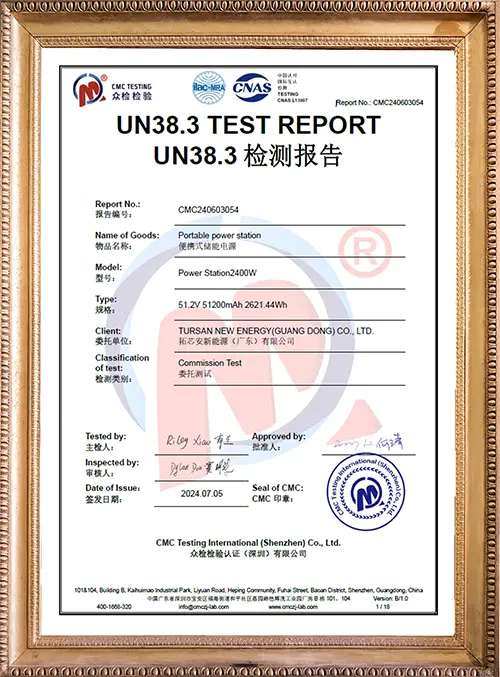

- UN38.3/MSDS/UL/CE/FCC | Free Customs Clearance Certificate Package

- 50-member R&D team | 7-day customized design, 15-day sample delivery | 25~30 days bulk delivery

Portable Power Stations Built with BYD Batteries

⚡ “23% lower cost of 1 kWh”

Germany’s EcoPower saves 17% of development costs with this program

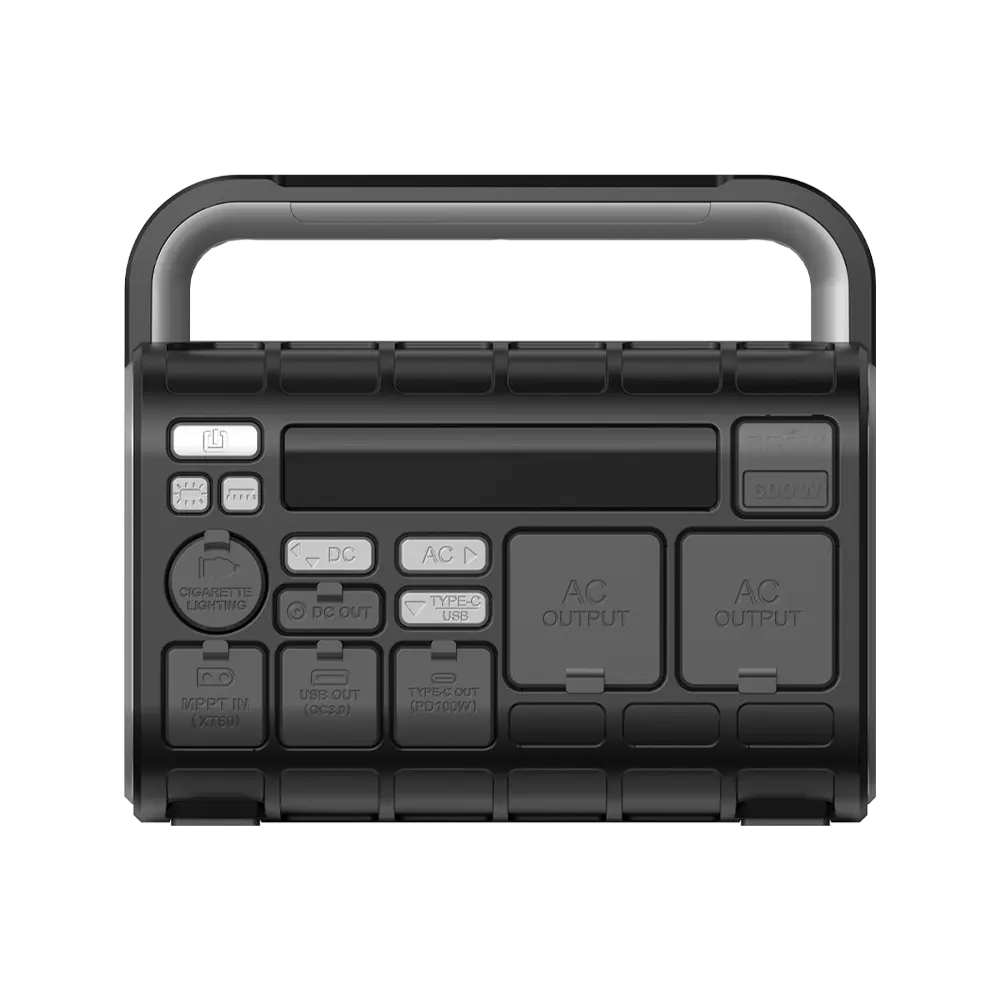

YC300S Portable Power Station | 328Wh | Starting from 200 units

- BYD LiFePO4 battery cell, 4000 times cycle life

- 7 output ports + 3W emergency light, adapts to wholesale camping equipment

- Solve the pain point:

✅ Cell traceability (battery QR code verification)

✅ Customs clearance risk (standardized UN38.3/MSDS/UL/CE/FCC)

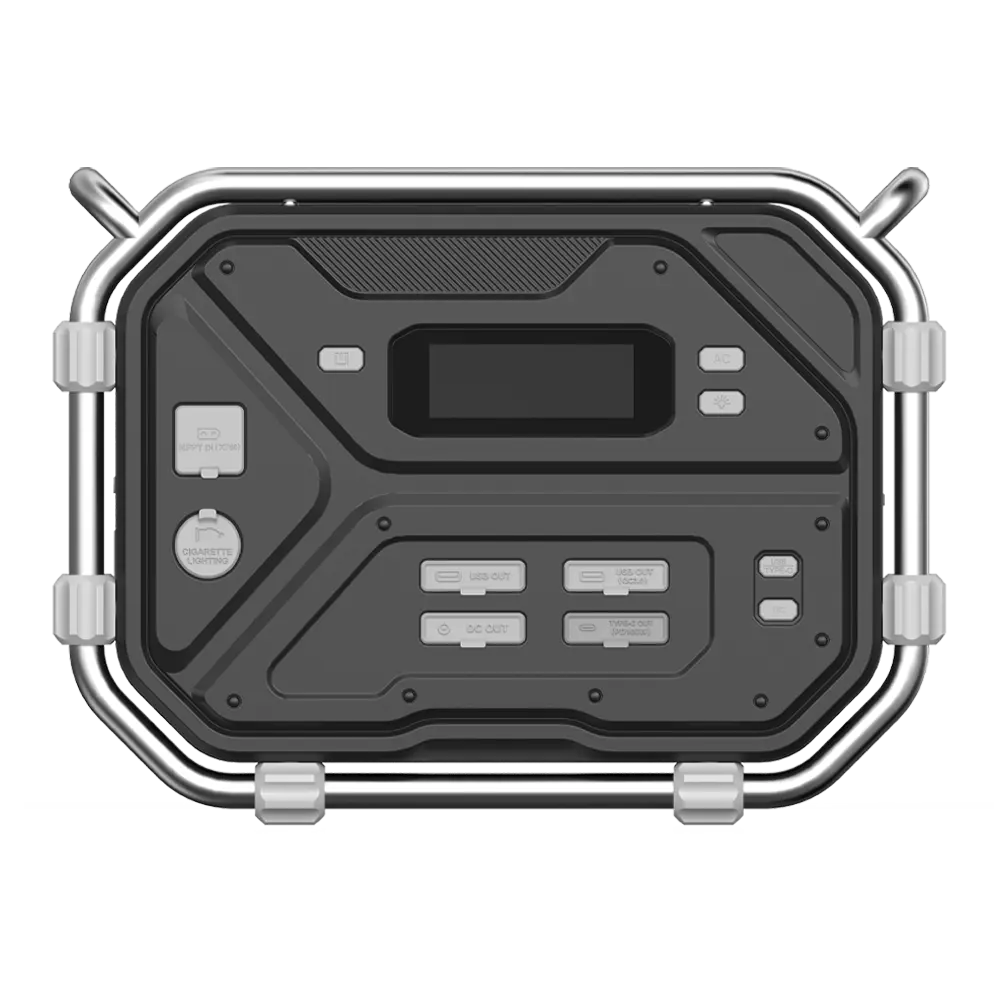

YC2400 Three-Phase Electric System | 2621Wh | Supports 3 machines parallel connection

- Extended capacity up to 15726Wh, designed for outdoor wholesale energy storage

- Exclusive agent enjoys regional protection + priority for private model development

- Solve the pain point:

✅ Exclusive rights and interests (guaranteed by legal agreement)

✅ Maintenance efficiency (faulty machine free to return to the factory for a new one)

YC600S Extreme Charge & Discharge | 655Wh | 7 Days Europe & USA Arrival

- 450W Bi-directional fast charging + 9 output ports, UL certified model

- North America warehouse spot direct shipment, to avoid the risk of shipping delays

- Solve the pain point:

✅ Delivery timeframe (lightning delivery of inventory)

✅ Price volatility (12-month cost lock-in)

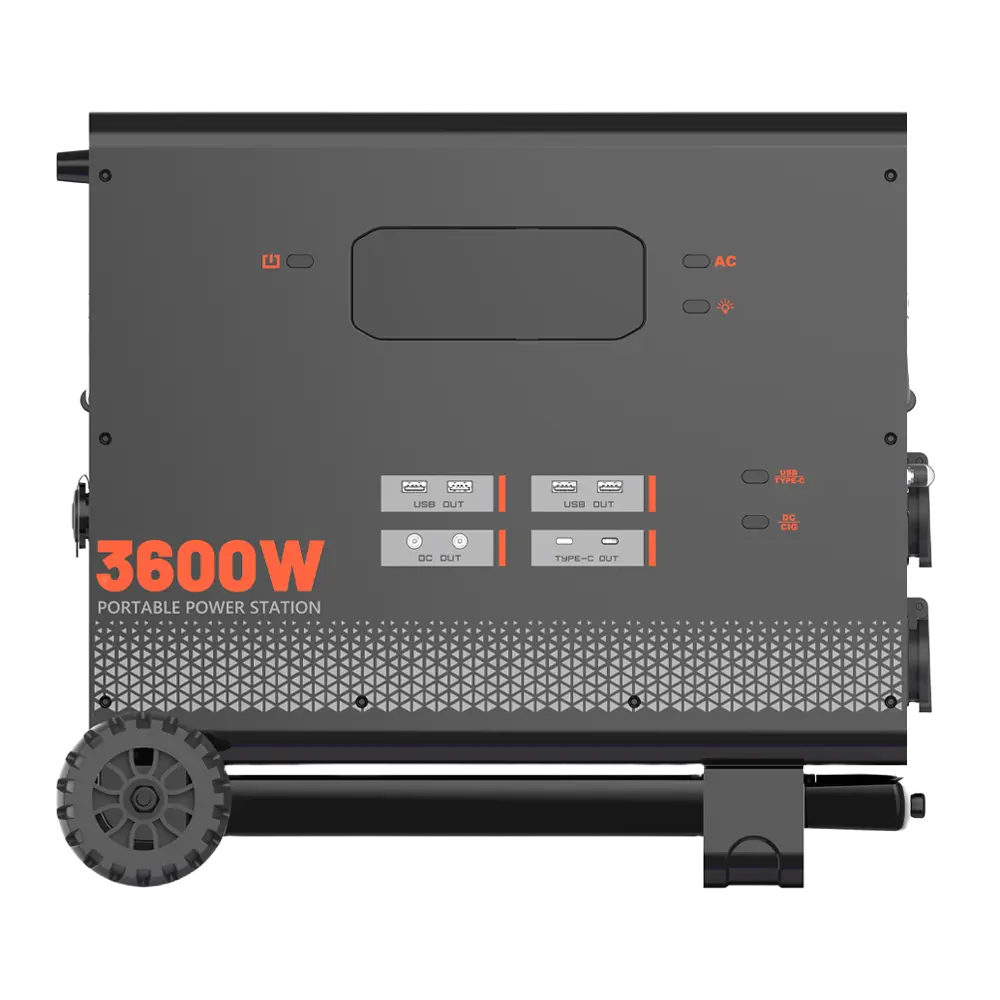

YC3600 Industrial Grade Power Station | 3932Wh | No MOQ Restriction

- Support three-phase grid-connected electricity, compatible with solar expansion

- 3-year full warranty + lifetime supply of accessories at cost price

- Solve the pain point:

✅ After-sales cost (spare parts are shipped directly from 6 warehouses worldwide)

✅ Complete certification (MSDS/ROHS full coverage)

Private Mold ODM Program | 7 Days Drawing | Zero Development Fee

- Supported by 50-member R&D team: appearance/outlet/UI customization

- Free Competitor Analysis + Patent Avoidance Solution

- Solve the pain points:

✅ Appearance similarity (exclusive design copyright)

✅ Development cycle (15 days sample delivery)

B2B Exclusive Guarantee | 10% Quality Guarantee for Orders

- Release the deposit after acceptance, cooperation throughout the zero risk

- Free of charge: VMI inventory hosting + 3D design drafts

- Solve the pain points:

✅ Security of funds (bank supervised account)

✅ Transparent production (sweep the code to view the workshop live)

Vantage Output/Pain Points Solved

Your Exclusive Customization | 15 Days Sample Delivery | Zero Development Fee

From concept to mass production: Supported by a 50-person R&D team to help you create a differentiated hit!

Only 3 authorized suppliers in China, support the scanning code authenticity + video factory inspection

7 days to complete exterior/outlet design, 15 days to deliver functional samples

All pre-installed UN38.3/MSDS/UL/CE/FCC certification, free patent avoidance program

Regional market protection agreement, support for private model development + LOGO customization

Solve Your Pain Points in Depth

| ❓Your Challenge | ✅TURSAN Solution |

|---|---|

| Excessively long development cycles | 15-day sample delivery, 40% faster than industry average |

| Serious homogenization and competition | Exclusive look/UI design supported by a team of 50 people |

| Incomplete certification leads to delayed customs clearance | Full certification as standard + free guide to customs declarations |

| Price volatility affects profits | 12-month battery cost lock-in agreement |

Vantage/Pain Point Specialization

🔥”3 more outlets than industry standard”

⚡ “23% lower cost for 1 kWh of electricity”

Industrial Grade Power Output | 4000 Cycle Life Guarantee

Adopting BYD’s power grade LiFePO4 batteries to meet wholesalers’ demand for both stability and cost-effectiveness

- 328Wh~3932Wh full scenario coverage, suitable for outdoor equipment/family backup/commercial energy storage

- Passed the extreme tests of pinprick/overcharge/high/low temperature to ensure 0 risk of spontaneous combustion.

- Solve Pain Points

✅ Cell traceability anxiety (Lifetime QR code tracking system for batteries)

✅ Maintenance Cost Concerns (48 hours replacement for faulty machine, no return to factory)

UN38.3/MSDS/UL/CE/FCC pre-certification | 40% increase in customs clearance time

Complete certificate package comes standard from the factory, eliminating technical barriers to cross-border trade.

- MSDS/ROHS/UL multiple certificates, suitable for Europe, America, Japan and Korea mainstream market.

- Provide free customs declaration code suggestions + competitor benchmarking parameter table

- Solve the pain points

✅ Incomplete certification leads to container detention (legal team to escort the whole process)

✅ Appearance patent infringement risk (free patent avoidance program)

From 200 Units → to Exclusive Distributor | Full-stage B2B Cooperation Programs

Supported by a 50-person R&D team, customized design iterations are completed in 7 days

- Small and micro wholesalers: 200 units of lightning delivery, support mixed batch SKUs

- Large customers: open exclusive agency rights + priority for private model development

- ODM buyers: free Amazon Best Seller replica program

- Solve the pain points

✅ Excessive MOQ leads to inventory backlog (lowest MOQ in the industry)

✅ Homogenized competition (regional market protection agreement)

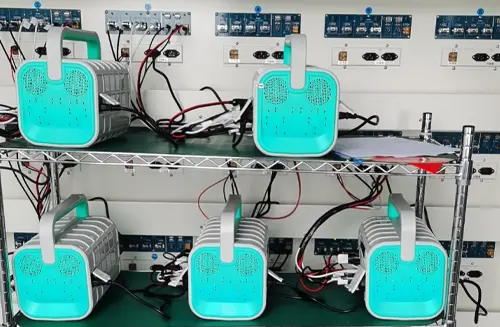

Why Choose TURSAN?

BYD’s direct supply of battery cells + full chain visualization production, building a zero-risk cooperation ecosystem for global wholesalers

- Only 3 BYD authorized in China (Huawei/Daqin/TURSAN), each battery is equipped with unique traceability QR code.

- Support video factory inspection and live broadcast of production workshop to witness the integration process of power-grade LiFePO4 battery cells.

- The whole series passes UN38.3/MSDS/UL/CE/FCC certification, and meets Walmart/Amazon access specifications

- 4000 cycles of actual test data publicized, 35% longer than the industry average life expectancy

- Supported by a 50-member R&D team: ⚡ “15-day sample delivery, 40% faster than peers”.

- Exclusive agent to enjoy the rights and interests of private model development, provide regional market protection legal agreement

Success Stories

I’ve copied my main contact, Mavis from TURSAN Solutions, on this message. Let me begin by noting that I reached out to her first to outline our specific requirements for the EcoPower project. This was following our initial technical consultation. She provided a comprehensive feasibility analysis within 48 hours, demonstrating exceptional technical responsiveness – a critical factor given our EU compliance deadlines.

For the EcoPower tender, we virtually evaluated 5 energy solution providers across Asia through technical proposals and system simulations. TURSAN became the final candidate after stress-testing their battery traceability integration with BYD’s cell database – a requirement for our bid’s sustainability credentials. Their Dongguan team even replicated our industrial design workflows using AR collaboration tools during the virtual factory audit.

TURSAN’s vertically integrated production model allowed them to compress prototyping-to-mass production to 17 days while maintaining EN 45552 certification standards. Their value engineering team redesigned the housing using modular tooling, directly contributing to the 23% cost reduction. Mavis’s group also coordinated with our Stuttgart designers to implement region-specific aesthetic adaptations without delaying CTF timelines.

We endorse TURSAN unreservedly for OEM energy projects requiring both agility and compliance rigor. While physical audits are advisable for new partners, their digital twin system (validated during our engagement) can substitute for 80% of onsite checks – a viable cost-saving alternative given our proven results.

When our desert solar project demanded 1,200 rugged portable power stations capable of surviving UAE sandstorms, TURSAN’s engineering team delivered a solution within 48 hours that exceeded every durability benchmark. Their cross-functional task force—spanning R&D, logistics, and field testing—mobilized before our contract was even finalized, proving their unmatched responsiveness to high-stakes challenges.

The true test came during accelerated environmental trials: TURSAN’s 2,400W units endured 500+ hours of 55°C thermal cycling and sand ingress simulations while maintaining 98% operational uptime. What impressed us most wasn’t just the product’s resilience, but how seamlessly their Dongguan engineers coordinated with Dubai-based quality auditors to implement real-time design tweaks during testing—a feat requiring military-grade synchronization across time zones.

TURSAN’s supply chain mastery shone brightest during delivery: They navigated Ramadan logistics constraints to airlift components from 8 specialized suppliers, then assembled units locally in Dubai South while our team monitored progress via live production feeds. The result? 1,200 battle-ready power stations deployed in 22 days—30% faster than industry standards—with full IEC 60529 IP67 certification and Arabic/English compliance documentation.

For Middle Eastern operators who view equipment durability as non-negotiable and timelines as sacred, TURSAN has set a new paradigm. Their ability to harden technology against nature’s extremes while maintaining clockwork operational precision makes them the silent backbone behind desert energy revolutions.

Workflows

Idea

Any thoughts you have

2D drawings

Confirmation Designs

3D Design

Confirmation of the complete structure

Proto-type

Avoid mold scrapped

Mold

Mold Lead time

Sample

Bulk Pre-production sample

Test

Smaple Test

Produce

Mass Production Produce

Accessories

Charger+Manuals, etc.

Color Printing Box

Exquisite Gift Box

UN BOX

Compliant Transportation

Shipment

Agile Shipping